Welcome to GM Tech

Welcome to GM Tech

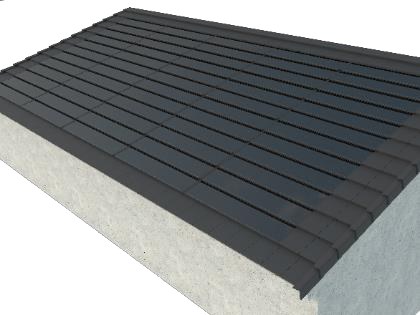

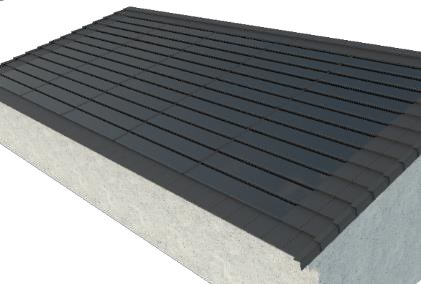

As a model of new electric building materials, the stacked photovoltaic tiles adopt monocrystalline double-glass module structure, strictly follow the international and domestic building integrated photovoltaic (BIPV) standard system, and are precision manufactured in an intelligent closed factory, with an integrated 24-hour production monitoring system to ensure traceable quality. The product has a positive pressure of 5400Pa/back pressure of 2400Pa load resistance, passed the salt spray, humidity and heat, hail and other harsh weathering tests, and is committed to a 30-year long-lasting power warranty. Its lightweight design takes into account roof load-bearing safety and construction convenience, realises the deep integration of architectural aesthetics and energy efficiency, and is complemented by professional power station cleaning services, providing a full life-cycle solution for green buildings.

Features

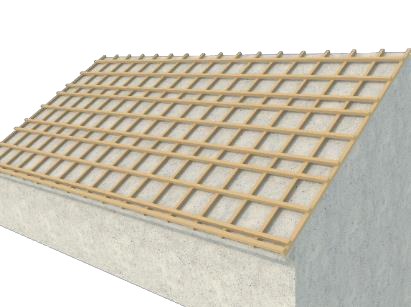

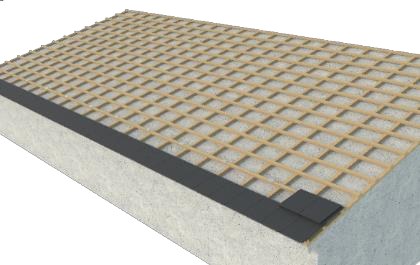

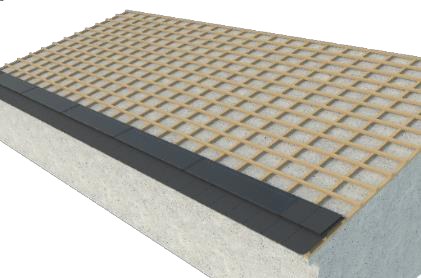

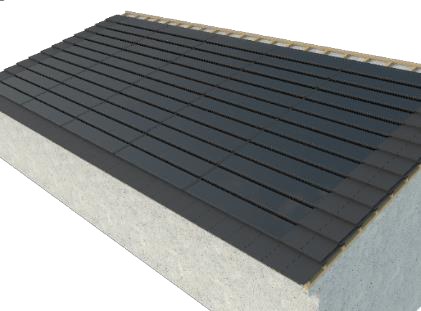

Stacked photovoltaic tiles adopt the design of hanging tile structure, which highly restores the roof installation structure of civil buildings, and perfectly integrates with the building.

The building blocks are overlapped, connected by upper and lower hooks, and fastened with screws. The installation is easy and can be completed by one person in one easy step.

Inclined system design, upper and lower frameless design, dustproof and no water accumulation, reduce roof shading, ensure building waterproof and improve power generation.

The double-glazed modular design combined with high-quality fittings ensures a 30-year service life for the system, avoids the need for mid-life replacement parts and reduces system wear and tear costs.

Parameter

Electrical Parameters(STC)

| Module Model | LDM109 | LDM112 | LDM115 |

| Maximum Power(Pmax/W) | 109 | 112 | 115 |

| Open Circuit Voltage(Voc/V) | 8.25 | 8.30 | 8.40 |

| Short Circuit Current(Isc/A) | 18.21 | 18.30 | 18.39 |

| Maximum Power Voltage(Vmpp/V) | 6.40 | 6.55 | 6.69 |

| Maximum Power Current(Impp/A) | 17.03 | 17.11 | 17.19 |

| FF% | 72.55 | 73.74 | 74.45 |

| Standard testing conditions: lrradiance -1000W/m'; cell temperature - 25'C;atmospheric mass-AM1.5 | |||

Mechanical Parameters

| Cell | 210mm monocrystal |

| Product Size | 1817mm*420mm*29mm |

| Module Size | 1732mm*418.5*5mm |

| Weight | 9.6kg |

| Structure | Double-glass |

| Frame | Black aluminum |

| Cable | 700mm positive&700mm negative |

| Connector | PV-SY02,IP68 |

| Junction Box and Diode | IP67,1000VDC,Two diodes |

Temperature Parameters &Application Environment

| NMOT | 44℃±2℃ |

| Temperature Coeffivient of Open Circuit Voltage(β) | -0.25%℃ |

| Temperature Cofficient of Short Circuit Current(α) | 0.04%℃ |

| Temperature Cofficient of Module Power | -0.34%℃ |

| Operating Temperature Range | -40℃~85℃ |

| Maximum System Voltage | 1000VDC |

| Maximum Fuse Current Rating | 30A |

| Limited Reverse Current | 30A |

PV Tile Roofing System Installation

|

|

|

|

|

|

| Tile installation | Bottom cement tile | Photovoltaic tile installation 1 | Solar tile installation 2 | Ridge tile installation | Side tile installation |

Please Read On, Stay Posted, Subscribe, And We Welcome You To Tell Us What You Think.

Copyright @ 2026 GM Tech All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / Xml / Privacy Policy