Welcome to GM Tech

Welcome to GM Tech

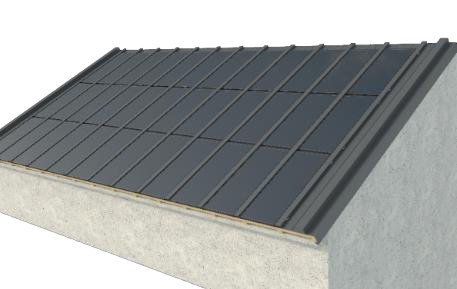

As an innovative green electricity building material, this flat photovoltaic tile perfectly integrates photovoltaic power generation function with building materials, bringing green energy solutions to buildings. The product meets the A-level fire protection standard, can effectively prevent the spread of fire, and greatly improve the fire safety of buildings. It has excellent performance in load resistance. It has passed the static mechanical load test of 5400Pa on the front and 2400Pa on the back, and can withstand external force impact in bad weather. It has strict weather resistance and can adapt to various complex climatic conditions, without fear of light, heat, wind and rain erosion. Thanks to the design of single crystal double glass frameless components, coupled with the intelligent closed factory production and 24-hour monitoring system, the product quality is stable and reliable, with a durability of up to 30 years. The photovoltaic tile is manufactured in strict accordance with various international and domestic industry standards. It not only realizes the integration of roof design, but also adopts lightweight operation, is easy to install, and meets the requirements of architectural aesthetics. While providing clean energy for the building, it ensures the beauty and coordination of the building's appearance. In addition, professional power station cleaning services are also provided to relieve users of worries.

Features

The tile type photovoltaic tiles embed high-efficiency power generation modules into the metal roof, deeply integrating them into an integrated form to build a metal roof that generates high-efficiency power.

The area of a single tile can reach 4.5 times that of a traditional cement tile, reducing the installation workload. It adopts a building block-style installation, which is easy to operate and can be installed by one person.

The power generation system uses double-glass frameless components with a self-cleaning function that can instantly remove dust and reduce power generation losses caused by dust accumulation.

The double-glass component design is combined with a combination of high-quality accessories to ensure a 30-year system life, avoid mid-term replacement of accessories, and reduce system loss costs.

Parameter

Electrical Parameters(STC)

| Module Model | LDM104 | LDM107 | LDM110 |

| Maximum Power(Pmax/W) | 104 | 107 | 110 |

| Open Circuit Voltage(Voc/V) | 14.99 | 15.22 | 15.43 |

| Short Circuit Current(Isc/A) | 8.90 | 8.99 | 9.08 |

| Maximum Power Voltage(Vmpp/V) | 12.41 | 12.63 | 12.85 |

| Maximum Power Current(Impp/A) | 8.38 | 8.47 | 8.56 |

| FF% | 77.95 | 78.20 | 78.51 |

| Standard testing conditions: lrradiance -1000W/m'; cell temperature - 25'C;atmospheric mass-AM1.5 | |||

Mechanical Parameters

| Cell | 210mm monocrystal |

| Product Size | 1378mm*564.8mm*17.2mm |

| Module Size | 1228mm*450*5mm |

| Weight | 8.8kg |

| Structure | Double-glass |

| Cable | 450mm positive&450mm negative |

| Connector | RHC2xyzu |

| Junction Box and Diode | IP67,1000VDC,One diodes |

Temperature Parameters &Application Environment

| NMOT | 44℃±2℃ |

| Temperature Coeffivient of Open Circuit Voltage(β) | -0.25%℃ |

| Temperature Cofficient of Short Circuit Current(α) | 0.04%℃ |

| Temperature Cofficient of Module Power | -0.34%℃ |

| Operating Temperature Range | -40℃~85℃ |

| Maximum System Voltage | 1000VDC |

| Maximum Fuse Current Rating | 15A |

| Limited Reverse Current | 15A |

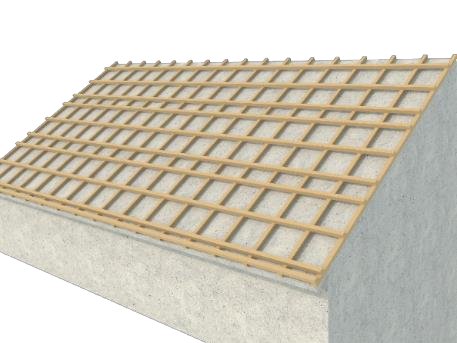

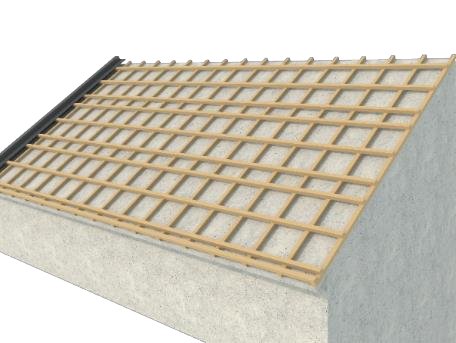

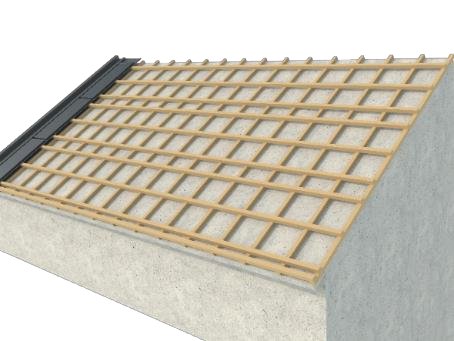

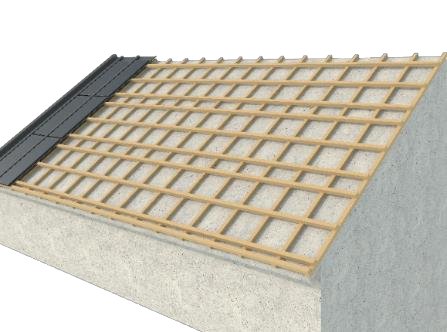

Roof photovoltaic tile installation

|

|

|

|

|

|

| Tile installation | Left side edge installation | Photovoltaic tile installation 1 | Solar tile installation 2 | Right side edge installation | Ridge tile installation |

Please Read On, Stay Posted, Subscribe, And We Welcome You To Tell Us What You Think.

Copyright @ 2026 GM Tech All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / Xml / Privacy Policy